RÜTSCHI CANNED MOTOR PUMPS

Safety and environmental protection

Canned motor technology

The safest solution for all types of fluids :

- Dangerous

- Toxic

- Volatile

- Malodorous

- Radioactive

- Expensive

The canned motor pump ensures absolute sealing in accordance with the CE requirements to reduce environmental pollution.

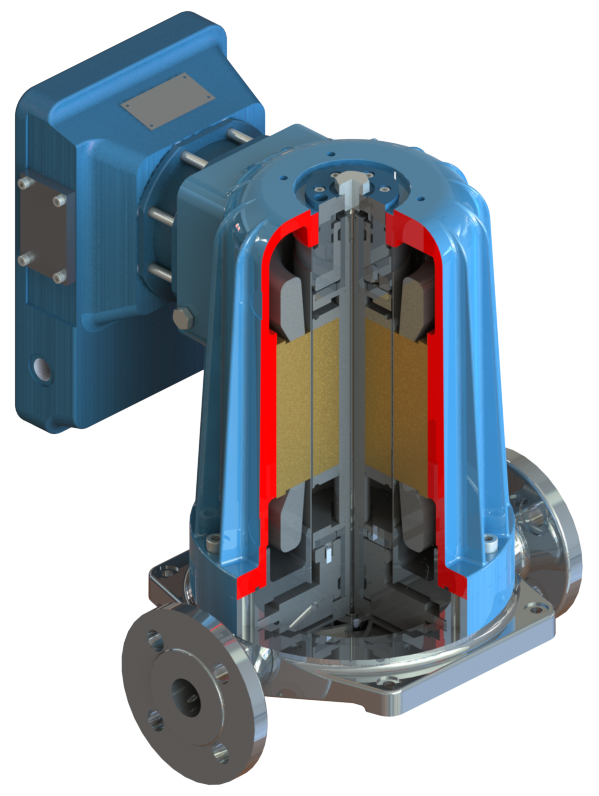

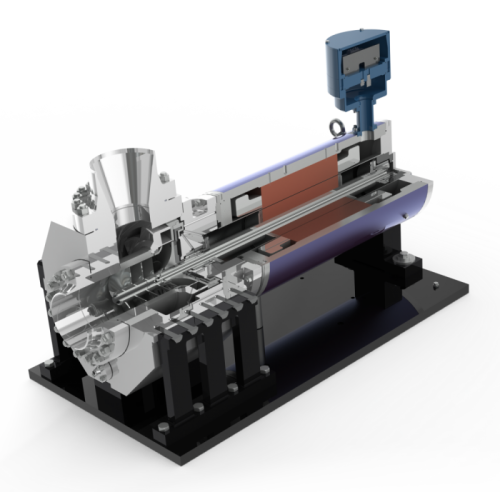

The “canned motor” is the most important part of a canned motor pump. The two main parts of the motor, the stator and the rotor, are separated from each other by a thin-walled pipe, the can, slipped into the gap between them. The impeller is mounted directly on the motor rotor.

The rotor rotates into the pumped liquid, supported by two medium-lubricated slide bearings. The can, as developed by Rütschi, is welded at both ends to the bearing supports and the can flange.

Any leakage of the pumped liquid into the stator is thus impossible. The pumped liquid flowing around the rotor and through the bearings is used for cooling and lubrication.

The can is easily replaceable and this is of great advantage in enabling the refitting with cans made of a different material and for easy access and repair of the stator winding.

The Rütschi canned motor pump is designed to ensure reliability and long service life thanks to its special construction features: no dynamic seals required, absolutely leak-tight, simple and robust, developed in complete module system with easy interchangeability of all parts, reduced maintenance load.

- Environmental protection

- Extremely Low Noise and Vibration

- Low Life Cycle Cost (LCC) : long life and economical maintenance

- Simple installation

PRODUCTS

Discover our ranges of pumps